Motors play a key role in many motion control functions in many industries such as packaging, food and beverage, manufacturing, medical treatment and robotics. We can choose from several motor types according to function, size, torque, accuracy and speed requirements.

As we all know, motor is an important part of transmission and control system. With the development of modern science and technology, the focus of motor in practical application has begun to shift from simple transmission to complex control; Especially for the accurate control of motor speed, position and torque. However, motors have different designs and driving modes according to different applications. At first glance, it seems that the selection is very complex. Therefore, for people, basic classification is carried out according to the purpose of rotating motors. Next, we will gradually introduce the most representative, commonly used and basic motors - control motor, power motor and signal motor.

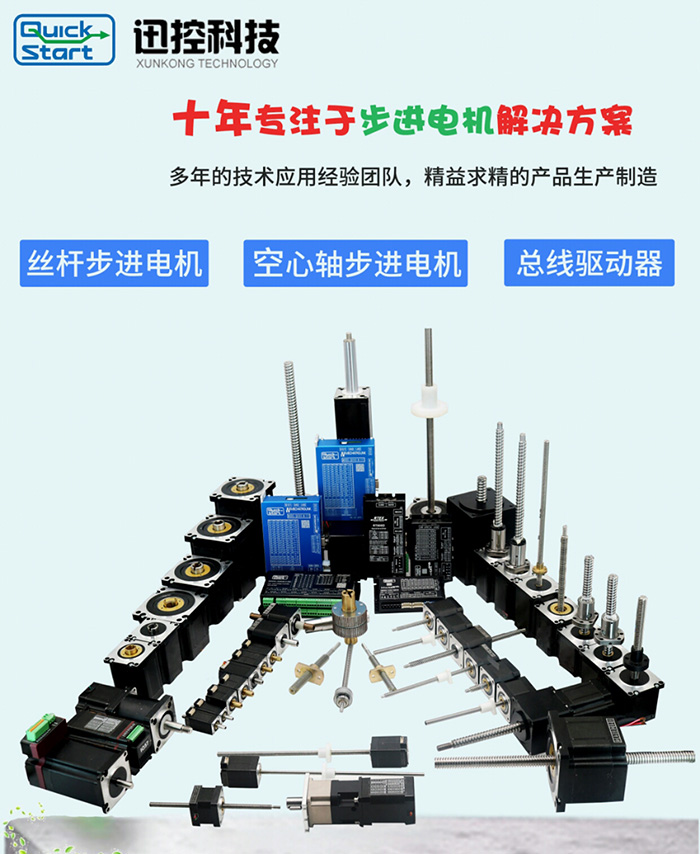

The control motor is mainly used in accurate speed and position control, and is used as "actuator" in the control system. It can be divided into servo motor, stepping motor, torque motor, switched reluctance motor, DC brushless motor and so on.

Servo motor is widely used in various control systems. It can convert the input voltage signal into the mechanical output on the motor shaft and drag the controlled components to achieve the purpose of control. Generally, the speed of servo motor is required to be controlled by the applied voltage signal; The rotating speed can continuously change with the change of the applied voltage signal; The torque can be controlled by the current output by the controller; The response of the motor should be fast, the volume should be small and the control power should be small. Servo motor is mainly used in various motion control systems, especially servo system.

Servo motors can be divided into DC and ac. the earliest servo motors were general DC motors. When the control accuracy was not high, general DC motors were used as servo motors. At present, with the rapid development of permanent magnet synchronous motor technology, most servo motors refer to AC permanent magnet synchronous servo motor or DC brushless motor.

The so-called stepping motor is an actuator that converts electric pulse into angular displacement; More generally speaking, when the stepping driver receives a pulse signal, it drives the stepping motor to rotate a fixed angle in the set direction. We can control the angular displacement of the motor by controlling the number of pulses, so as to achieve the purpose of accurate positioning; At the same time, the speed and acceleration of motor rotation can be controlled by controlling the pulse frequency, so as to achieve the purpose of speed regulation. At present, the commonly used stepping motors include reactive stepping motor (VR), permanent magnet stepping motor (PM), hybrid stepping motor (HB) and single-phase stepping motor.

The difference between stepper motor and ordinary motor mainly lies in the form of pulse drive. It is this characteristic that stepper motor can be combined with modern digital control technology. However, the stepper motor is inferior to the traditional closed-loop DC servo motor in control accuracy, speed variation range and low-speed performance; Therefore, it is mainly used in occasions where the accuracy requirement is not particularly high. Because stepping motor has the characteristics of simple structure, high reliability and low cost, stepping motor is widely used in various fields of production practice; Especially in the field of NC machine tool manufacturing, because the stepping motor does not need a / D conversion and can directly convert the digital pulse signal into angular displacement, it has been considered as the most ideal actuator of NC machine tool.

In addition to its application in CNC machine tools, stepper motors can also be used in other machines, such as motors in automatic feeders, motors in general floppy disk drives, printers and plotters.

In addition, stepper motor also has many defects; Because the stepper motor has no-load starting frequency, the stepper motor can operate normally at low speed, but it cannot be started if it is higher than a certain speed, accompanied by sharp whistling; The precision of subdivision drivers from different manufacturers may vary greatly. The greater the subdivision, the more difficult it is to control the precision; Moreover, the stepping motor has large vibration and noise when rotating at low speed.

The so-called torque motor is a flat multipole permanent magnet DC motor. The armature has more slots, commutators and series conductors to reduce torque ripple and speed ripple. There are two kinds of torque motors: DC torque motor and AC torque motor.

Among them, the self inductance reactance of DC torque motor is very small, so the response is very good; The output torque is directly proportional to the input current and has nothing to do with the speed and position of the rotor; It can directly connect with the load at low speed without gear deceleration when it is close to the locked rotor state, so it can produce a high torque to inertia ratio on the load shaft and eliminate the system error caused by the use of reduction gear.

AC torque motor can be divided into synchronous and asynchronous. At present, squirrel cage asynchronous torque motor is commonly used, which has the characteristics of low speed and strong torque. Generally, AC torque motor is often used in textile industry. Its working principle and structure are the same as that of single-phase asynchronous motor. However, due to the large resistance of squirrel cage rotor, its mechanical characteristics are soft.

Switched reluctance motor is a new type of speed regulating motor, which has extremely simple and firm structure, low cost and excellent speed regulating performance. It is a strong competitor of traditional control motor and has strong market potential. However, there are also some problems such as torque ripple, running noise and large vibration, which need some time to optimize and improve to adapt to the actual market application.

Brushless DC motor (BLDCM) is developed on the basis of Brushless DC motor, but its driving current is AC; Brushless DC motor can be divided into brushless speed motor and brushless torque motor. Generally, there are two kinds of driving current of brushless motor, one is trapezoidal wave (generally "square wave"), and the other is sine wave. Sometimes, the former is called brushless DC motor, and the latter is called AC servo motor. To be exact, it is also a kind of AC servo motor.

In order to reduce the moment of inertia, brushless DC motor usually adopts "slender" structure. Brushless DC motor is much smaller in weight and volume than brushless DC motor, and the corresponding moment of inertia can be reduced by about 40% - 50%. Due to the processing problem of permanent magnet materials, the general capacity of Brushless DC motor is less than 100kW.

This kind of motor has good linearity of mechanical characteristics and regulation characteristics, wide speed regulation range, long service life, convenient maintenance, low noise and no series of problems caused by brush. Therefore, this kind of motor has great application potential in control system.

DC motor is the earliest motor. At the end of the 19th century, it can be roughly divided into two categories: commutator and non commutator. DC motor has better control characteristics. DC motor is not as good as AC motor in structure, price and maintenance. However, the speed regulation control problem of AC motor has not been well solved, and DC motor has the advantages of good speed regulation performance, easy starting and load starting. Therefore, DC motor is still widely used at present, Especially after the emergence of thyristor DC power supply.

Application status: in life, there are countless applications of electric products. Fan, razor, etc. DC motors are used in automatic doors, automatic door locks and automatic curtains in hotels. DC motors are widely used in aircraft, tanks, radar and other weapons and equipment. DC motor is also widely used in locomotive traction, such as railway locomotive DC traction motor, Metro locomotive DC traction motor, locomotive DC auxiliary motor, mining locomotive DC traction motor, marine DC motor, etc.

Asynchronous motor is an AC motor which realizes energy conversion based on the electromagnetic torque generated by the interaction between air gap rotating magnetic field and rotor winding induced current. Asynchronous motors are generally series products with a wide variety of specifications. They are most widely used in all motors and have the largest demand; At present, about 90% of machinery in electric drive uses AC asynchronous motor, so its power consumption accounts for more than half of the total power load.

Asynchronous motor has the advantages of simple structure, convenient manufacture, use and maintenance, reliable operation, low quality and low cost. Moreover, the asynchronous motor has high operation efficiency and good working characteristics. It runs at a constant speed from no-load to full load, which can meet the transmission requirements of most industrial and agricultural production machinery. Asynchronous motors are widely used to drive most industrial and agricultural production machinery, such as machine tools, water pumps, blowers, compressors, hoisting equipment, mining machinery, light industrial machinery, agricultural and sideline products processing machinery, as well as household appliances and medical devices.

Application status: single phase asynchronous motor and three-phase asynchronous motor are more common in asynchronous motors. Three phase asynchronous motor is the main body of asynchronous motor. Three phase asynchronous motor can be used to drive all kinds of general machinery, such as compressor, water pump, crusher, cutting machine tool, transportation machinery and other mechanical equipment. Mechanics. It is used as prime mover in various industrial and mining enterprises such as metallurgy, petroleum, chemical industry and power station. For motors used to drive blowers, coal mills, rolling mills and hoists, relevant technical data shall be provided when ordering, and technical agreements shall be signed as the basis for special design of motors to ensure reliable operation of motors.. Single phase asynchronous motors are generally used where three-phase power supply is inconvenient. Most of them are micro and small capacity motors, which are widely used in household appliances, such as electric fans, refrigerators, air conditioners, vacuum cleaners, etc.

The so-called synchronous motor is a motor driven by alternating current, and the rotating magnetic field of rotor and stator runs synchronously. The stator of synchronous motor is exactly the same as that of asynchronous motor; However, there are two kinds of rotors: salient pole type and hidden pole type. Salient pole rotor synchronous motor has simple structure and convenient manufacture, but its mechanical strength is low, so it is suitable for low-speed operation; The manufacturing process of hidden pole synchronous motor is complex, but its mechanical strength is high. It is suitable for high-speed operation. The working characteristics of synchronous motor are the same as all motors. Synchronous motor also has "retrograde", that is, it can operate in the mode of generator or motor.

Application status: synchronous motors are mainly used in large machinery, such as blowers, water pumps, ball mills, compressors, rolling mills, small and micro instruments and equipment, or as control components; The three-phase synchronous motor is its main body. In addition, it can also be used as a condenser to transmit inductive or capacitive reactive power to the power grid.

Asynchronous motor has the advantages of simple structure, convenient manufacture, use and maintenance, reliable operation, low quality and low cost. Moreover, the asynchronous motor has high operation efficiency and good working characteristics. It runs at a constant speed from no-load to full load, which can meet the transmission requirements of most industrial and agricultural production machinery. Asynchronous motors are widely used to drive most industrial and agricultural production machinery, such as machine tools, water pumps, blowers, compressors, hoisting equipment, mining machinery, light industrial machinery, agricultural and sideline products processing machinery, as well as household appliances and medical devices.

Application: single phase asynchronous motor and three-phase asynchronous motor are more common in asynchronous motor, in which three-phase asynchronous motor is the main body of asynchronous motor. Single phase asynchronous motors are generally used where three-phase power supply is inconvenient. Most of them are micro and small capacity motors, which are widely used in household appliances, such as electric fans, refrigerators, air conditioners, vacuum cleaners, etc.

At present, the most representative position signal motors are resolver, inductosyn and synchro.

Introduction: resolver / transformer is an electromagnetic sensor, also known as synchronous resolver. It is a small AC motor for measuring angle, which is used to measure the angular displacement and angular velocity of the rotating shaft of the rotating object. It is composed of stator and rotor. As the primary side of the transformer, the stator winding receives the excitation voltage, and the excitation frequency is usually 400, 3000 and 5000Hz. As the secondary side of the transformer, the rotor winding obtains the induced voltage through electromagnetic coupling.

Application status: resolver is a precision angle, position and speed detection device, which is suitable for all resolver resolver resolver occasions using rotary encoder, especially those where rotary encoder cannot work normally, such as high temperature, cold, humidity, high speed and high vibration. Due to the above characteristics, the resolver can completely replace the photoelectric encoder and is widely used in angle and position detection systems in servo control systems, robot systems, mechanical tools, automobiles, electric power, metallurgy, textiles, printing, aerospace, ships, weapons, electronics, metallurgy, mines, oil fields, water conservancy, chemical industry, light industry, construction and other fields. It can also be used for coordinate transformation, triangulation and angle data transmission. It can also be used as a two-phase phase shifter in angle digital conversion device.

The displacement sensor that converts the angular or linear displacement signal into AC voltage is also called planar resolver. It has two types: disc type and linear type. In high-precision digital display system or NC closed-loop system, disk inductosyn is used to detect angular displacement signal and linear inductosyn is used to detect linear displacement. Inductosyn is widely used in high-precision servo turntable, radar antenna, positioning and tracking of artillery and radio telescope, precision CNC machine tools and high-precision position detection system.

Application status: inductosyn has been widely used in large displacement static and dynamic measurement, such as CMM, program-controlled CNC machine tools, high-precision heavy machine tools and measuring devices of machining centers.

Inductosyn realizes displacement detection by using electromagnetic coupling principle, which has obvious advantages: high reliability, strong anti-interference ability, low requirements for working environment, can work normally without constant temperature control and bad environment, and is suitable for the harsh environment of industrial site; Grating sensor realizes displacement detection based on photoelectric mechanism. It has high resolution, accurate measurement and convenient installation and use. The closed grating sensor is more widely used in length measurement than inductosyn because of its strong adaptability to the working environment, the improvement of the performance price ratio of grating sensor and the reduction of technical complexity.

Synchro is an induction micro motor that changes the angle into AC voltage or from AC voltage to angle by using the characteristic of self-tuning step. It is used as a displacement sensor to measure the angle in the servo system. The synchro can also be used to realize the long-distance transmission, transformation, reception and indication of angle signals. Two or more motors automatically maintain the same angle change or synchronous rotation of two or more rotating shafts that are not connected to each other mechanically through circuit connection. This performance of the motor is called self-tuning characteristic. In the servo system, the synchro used by the party generating the signal is called the transmitter, and the synchro used by the party receiving the signal is called the receiver. Synchro is widely used in position and azimuth synchronous indication systems such as metallurgy and navigation, and servo systems such as artillery and radar.

Application status: the synchro can also be used to realize long-distance transmission, transformation, reception and indication of angle signal. Two or more motors automatically maintain the same angle change or synchronous rotation of two or more rotating shafts that are not connected to each other mechanically through circuit connection. This performance of the motor is called self-tuning characteristic. In the servo system, the synchro used by the party generating the signal is called the transmitter, and the synchro used by the party receiving the signal is called the receiver. Synchro is widely used in position and azimuth synchronous indication systems such as metallurgy and navigation, and servo systems such as artillery and radar.

The most representative speed signal motor is the tachogenerator, which is essentially an electromechanical magnetic element that converts the speed into an electrical signal, and its output voltage is directly proportional to the speed. In terms of working principle, it belongs to the category of "generator". The tachogenerator is mainly used as damping element, differential element, integral element and tachometer element in the control system. So I won't elaborate too much here.

1. According to the type of working power supply: it can be divided into DC motor and AC motor

2. According to the structure and working principle, it can be divided into DC motor, asynchronous motor and synchronous motor.

3. According to the starting and operation modes: capacitor starting single-phase asynchronous motor, capacitor running single-phase asynchronous motor, capacitor starting running single-phase asynchronous motor and split phase single-phase asynchronous motor.

4. Divided by purpose: drive motor and control motor.

5. According to the structure of rotor: cage induction motor (called squirrel cage asynchronous motor in the old standard) and wound rotor induction motor (called wound asynchronous motor in the old standard).

6. Divided by operating speed: high-speed motor, low-speed motor, constant speed motor and speed regulating motor. Low speed motors are divided into gear reduction motors, electromagnetic reduction motors, torque motors and claw pole synchronous motors.

Servo motor belongs to the control motor divided by purpose. Servo motor refers to the engine that controls the operation of mechanical components in the servo system. It is an indirect speed change device of auxiliary motor. The servo motor can control the speed and position accuracy very accurately, and can convert the voltage signal into torque and speed to drive the control object. In an automatic control system, it is used as an actuator to convert the received electrical signal into angular displacement or angular velocity output on the motor shaft. It is divided into DC and AC servo motors. Its main feature is that when the signal voltage is zero, there is no rotation, and the speed decreases at a uniform speed with the increase of torque.

Conditions related to model selection

1. Motor parameters: first understand the specification and model, functional characteristics, protection type, rated voltage, rated current, rated power, power frequency, insulation grade, etc. of the motor. These contents can basically provide a reference basis for users to correctly select protectors.

2. Environmental conditions: mainly refer to normal temperature, high temperature, high cold, corrosion, vibration, wind and sand, altitude, electromagnetic pollution, etc.

3. Purpose of motor: it mainly refers to the required characteristics of driving mechanical equipment, such as fan, water pump, air compressor, lathe, oilfield pumping unit and other mechanical characteristics of different loads.

4. Control mode: the control modes include manual, automatic, local control, remote control, independent operation of single machine, centralized control of production line, etc. The starting modes include direct, step-down, star angle, frequency sensitive rheostat, frequency converter, soft start, etc.

5. Other aspects: monitoring and management of on-site production by users, severity of impact of abnormal shutdown on production, etc.