When purchasing stepping motor, users will encounter a variety of problems, such as parameters, installation, maintenance and so on. The answers to the following common questions are for your reference. These questions are not only limited to micro DC motors, but also ordinary motors, stepper motors, aluminum shell motors, variable frequency motors, three-phase asynchronous motors and other motor problems.

What is the reason why the leakage short circuit breaker is easy to trip when using the frequency converter?

The waveform output by the frequency converter will have high-order harmonics, but the cable between the motor and the frequency converter and the motor will produce leakage current, which will be much larger than that when the motor is driven by power frequency, so tripping will occur. Since the leakage current output by the frequency converter is about 3 times of the power frequency current, plus the leakage current of the motor, the current of the leakage protector shall be greater than about 10 times of the power frequency current.

02 is it necessary to use variable frequency motor for variable frequency speed regulation experiment with motor?

If it is the flower of frequency conversion speed regulation experiment, it is not necessary to use frequency conversion motor. Ordinary AC motor and DC motor can also be used.

AC variable frequency motor is actually a motor that adjusts speed by adjusting AC frequency, mainly by frequency converter. Note: the motor itself does not have frequency conversion, and frequency conversion can be realized only by adding frequency converter to ordinary motor.

The DC motor frequency conversion is different. Take the DC motor frequency conversion air conditioner as an example: it converts the power frequency AC motor into DC, and then sends it to the power module. The model is controlled by microcomputer, and the controlled DC is sent to the DC motor of the compressor to control the displacement of the compressor to realize frequency conversion speed regulation.

03 function of reducer?

Reduce the output speed of the motor and increase the data torque.

04 why does the motor start slowly?

There are two situations. The first is that the speed is slow during startup and normal after startup, then the starting capacitance may not match; Or the motor design is just like this (the motor design is different in different application places); It is also possible that the load resistance is too high, resulting in too long starting time.

The second case is that the speed is still very slow after startup, so it is necessary to consider factors such as insufficient voltage, mismatched capacitance, large rotation resistance and so on.

05 how to choose the brush of asynchronous motor?

Firstly, it is necessary to know whether the working conditions of the brush can meet the current density and the linear speed of the circumferential edge of the collector ring, which can be determined by the formula:

Brush current carrying capacity = brush current density × Brush width × Brush thickness ≥ rated current of motor rotor

Linear speed at circumferential edge of collector ring = rated speed of motor × Perimeter of collector ring ≤ specified range of brush application

Brushes generally include graphite brush, metal brush, electrochemical graphite brush, etc. during use, pay attention to regularly check the brush activity, brush pressure and wear degree. The electric brush shall be able to move up and down freely in the brush holder without jamming. When clamping the brush, grind both sides of the brush on the abrasive cloth. The pressure of the brush shall be properly adjusted according to the type and model of the brush. At present, most of the brush compression springs attached to the brush holder are tension compression springs, and their pressure decreases gradually with the wear of the brush. Therefore, during the operation of the motor, the brush pressure should be adjusted at any time.

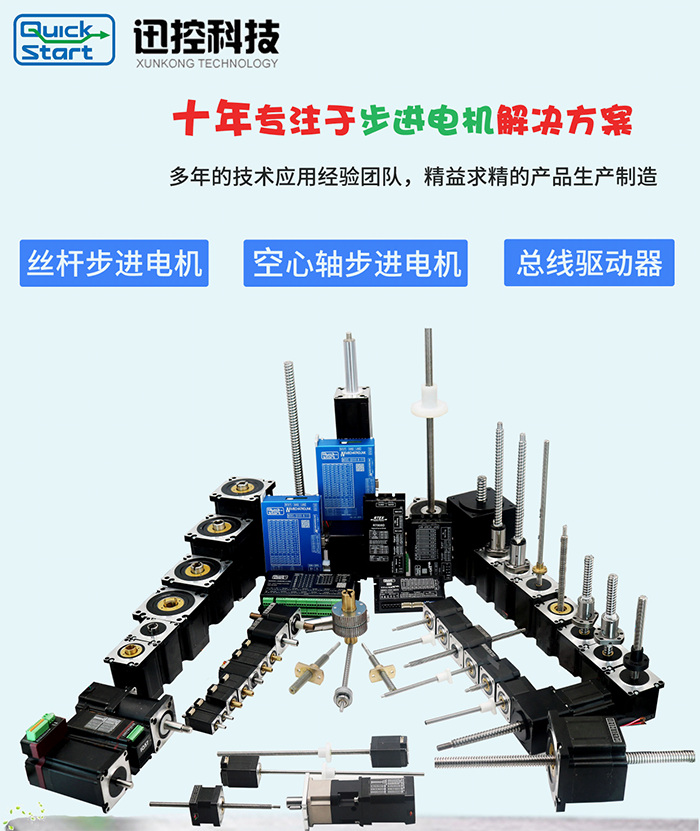

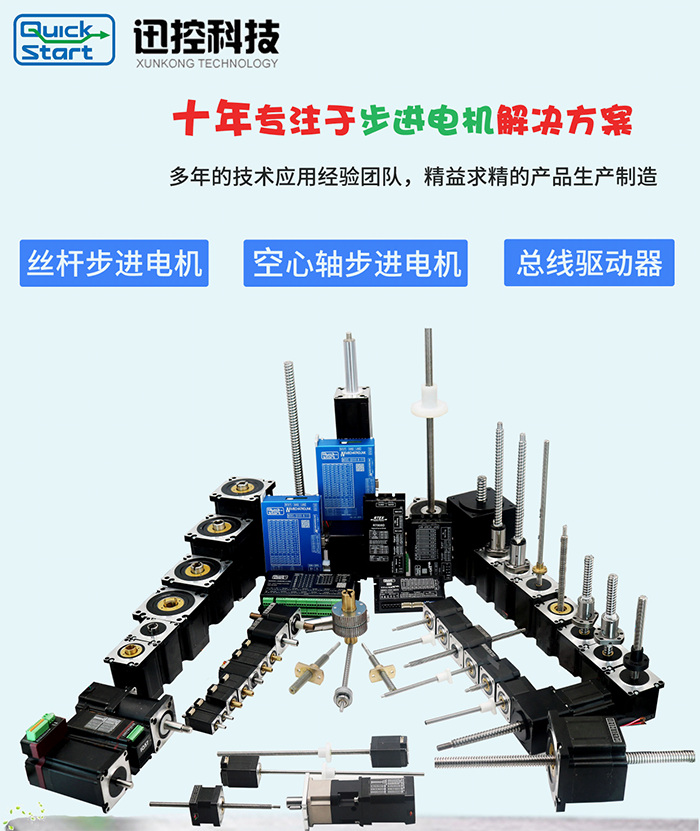

Quickmotor start Dongguan fast control automation specialty customizes all kinds of stepping motors

06 60Hz motor is used on 50Hz power supply. What should be paid attention to?

This is because the current frequency of the motor is lower than the design frequency. In order to reduce the no-load back electromotive force and increase the no-load current generated during its rotation, and cause damage to the motor, it is required to reduce its no-load voltage.

In variable frequency speed regulation technology, the frequency of motor and stator voltage change at the same time. That is, the frequency decreases and the voltage also decreases at the same time, so that the motor will not overcurrent and will get the ideal operation effect.

07 why should an output reactor be added at the output end of the frequency converter? What is its function?

The output reactor is added at the output end of the frequency converter to increase the wire distance from the frequency converter to the motor. The output reactor can effectively suppress the instantaneous high voltage generated when the IGBT switch of the frequency converter and reduce the adverse impact of this voltage on cable insulation and motor.

The main function of reactor is to limit the capacitive charging current of motor connecting cable and limit the voltage rise rate on motor winding to 540V/ μ Within s, it is also used to passivate the steepness of the output voltage (switching frequency) of the frequency converter and reduce the disturbance and impact of power components (such as IGBT) in the inverter.

08 can AC servo motor be controlled by frequency converter?

Due to the difference in performance and function between frequency converter and servo, the application is not the same, so it is not possible.

In the situation of speed control and torque control, the requirements are not very high. Generally, frequency converter is used. There are also closed-loop composed of upper position feedback signal and frequency converter for position control. The accuracy and response are not high. At present, some frequency converters also accept the pulse sequence signal to control the speed, but it seems that they can not directly control the position.

In the occasions with strict position control requirements, it can only be realized by servo. In addition, the response speed of servo is much higher than that of frequency conversion. Servo control is also used in some occasions with high requirements for speed accuracy and response. Servo can be used in almost all occasions where frequency conversion control can be used.

There are two key points: first, the price of servo is much higher than that of frequency conversion, and second, the reason for power: the maximum frequency conversion can achieve hundreds of kW or even higher, and the maximum servo is dozens of kW. The basic concept of servo is accurate, accurate and fast positioning. Frequency conversion is a necessary internal link of servo control. Frequency conversion (stepless speed regulation) also exists in servo driver.

09 can the speed regulating motor be started frequently?

Variable speed motors can be started frequently. The motors used for commissioning in our company are variable speed motors. They are often started so frequently, and there has been no problem. However, it is best to minimize frequent startup. No matter how often the motor is started, it will damage the motor.

10 how can I know that the motor is star / Delta?

The star connection method is that one end of the three-phase winding is connected, and the other end is connected to the three-phase power supply respectively, which is shaped like the letter "Y"; The delta connection method is that the three-phase windings are connected end to end to form a "△" shape, and the top of the triangle is connected to the three-phase power supply.

Their phase voltages are different. Generally, the rated voltage of motor in star connection method is 220V and that in triangle connection method is 380V. The connection method is generally indicated on the inside and outside of the cover plate of the junction box, and different connection methods correspond to different power supply voltages.

11 what is the influence of the number of poles of the motor on its selection?

At present, there are 2 / 4 / 6 / 8 motors, and the number of motors for special purposes may be higher. The more pole pairs of the motor, the lower the speed of the motor, but the greater its torque;

When selecting the motor, you should consider the starting torque required by the load. For example, the torque required for starting with load is larger than that for no-load starting. If it is high-power and high load starting, you should also consider step-down starting (or star delta starting);

As for the speed matching with the load after determining the number of poles of the motor, it can be considered to drive with belt pulley of different diameter or match with variable speed gear (Gearbox). If the power requirements of the load cannot be reached after determining the number of poles of the motor through belt or gear transmission, the use power of the motor must be considered.

12 what is a series motor and what is the specific principle?

Series excited (series excited) motor is a series of stator winding and rotor winding.

Working principle: the principle of generating rotating torque when powered by AC power supply can still be explained by the operation principle of DC motor. When there is current in the conductor, a magnetic field is generated around the conductor, and the direction of the magnetic line of force depends on the direction of the current. Put the electrified conductor into the magnetic field. The interaction between the magnetic field and the magnetic field generated by the electrified conductor will make the conductor subject to a force F and move accordingly. The conductor will move from the place where the magnetic lines of force are dense to the direction where the magnetic lines of force are sparse. When the coil composed of two opposite conductors is put into the magnetic field, the two sides of the coil will also receive a force, These two forces have opposite directions and produce torque. When the coil rotates in the magnetic field, when the corresponding two coil sides turn from one magnetic pole to the other, at this time, due to the change of the polarity of the magnetic field, the direction of the force on the conductor and the direction of the torque will change, so that the coil rotates in the opposite direction, so the coil can only swing back and forth around the central axis.